Lost your password? Please enter your email address. You will receive a link to create a new password.

Top Manufacturers

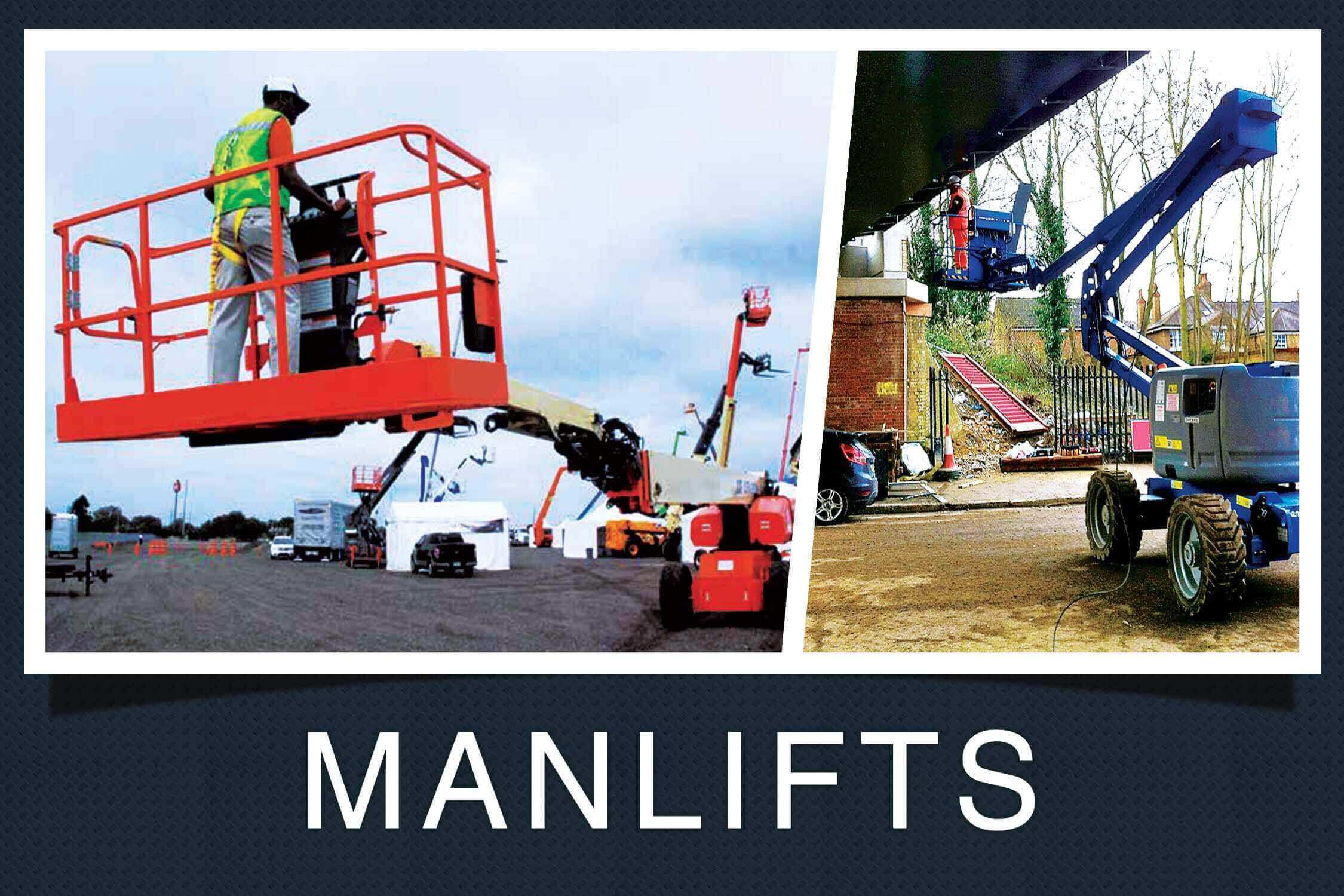

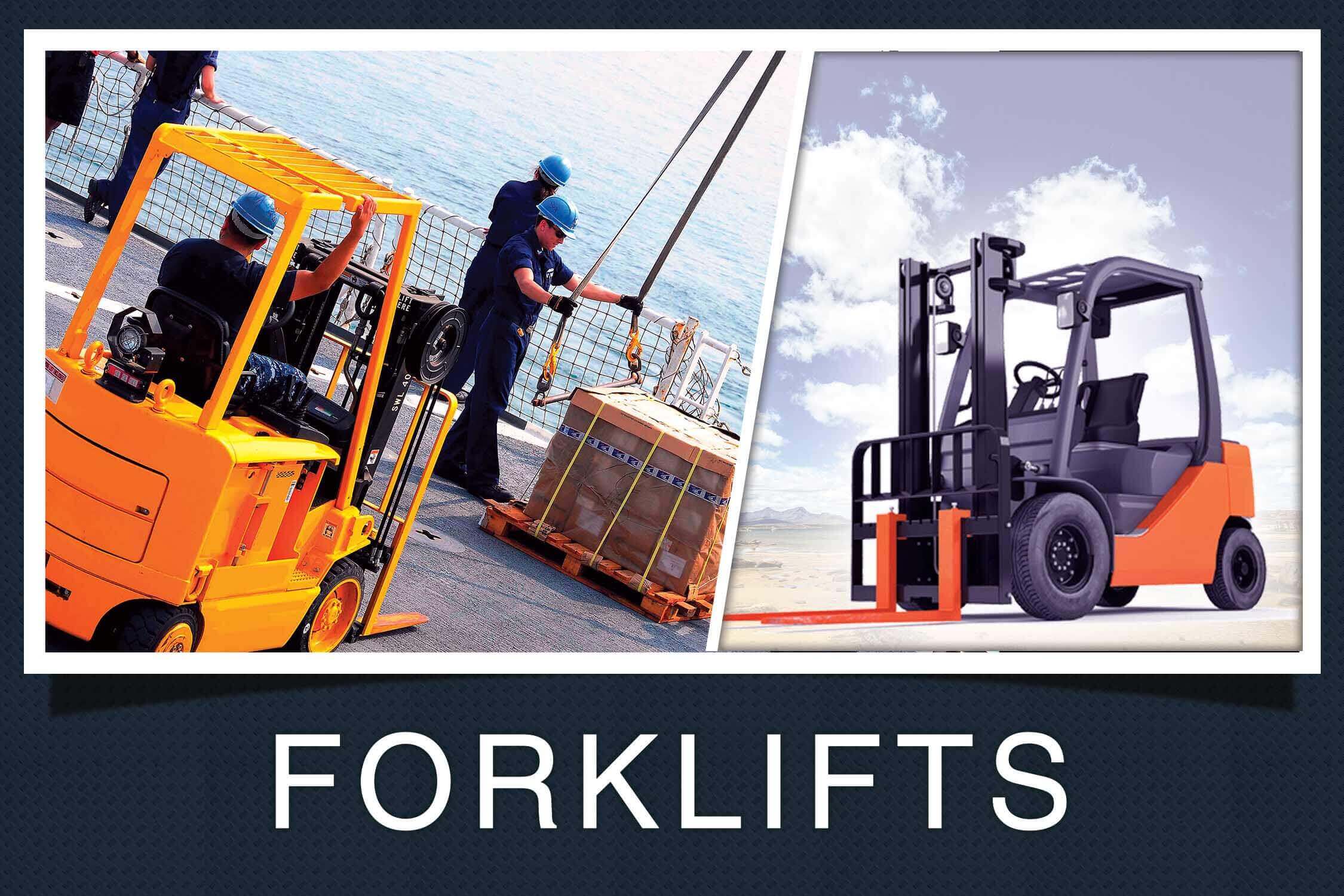

Crane Types Listed On CranePlus

Features Coming Soon

Operator On Demand

Soon we will provide well experienced operators as per your Real-Time Demand.

Mechanic On Demand

Best Mechanics will be provided as per Work / Repair requirement of your Equipment.

Crane Managing Software

You can manage all your Crane related Profit / Expense by using a Super Smart Software.

Insurance

You can get all your Cranes Insured any time on the Click of a Button.

Finance

Get immediate Finance on your Crane as per your Loan Requirement.

Free Load Charts

Get Free Crane Specification / Load Chart of any Crane Any-Time as per your need.

Payment Risk Cover

A System will take Payments from Client and that will be Credited directly to your Account.

Transportation

You can Transport your Equipment and get real time cost from Genuine Transporter.

Mobile App

All the Available Features will be on your Phone in the form of Simple Mobile App

Crane Information

Video : Self-isolation challenge Liebherr LTM11200 crane (27-01-2021)

With much of the world faced with the challenge of self-isolating following the outbreak of Covid-19, some crane fans are struggling to keep occupied, however this might provide you with a few ideas!

Professional Lego Technic modeller, Jeroen Ottens, has just finished creating a working large scale model of the 1,200 tonne Liebherr LTM 11200-9.1 All Terrain crane, complete with its Y-guying system and luffing jib from Lego Technic.

OK, truth be told, Ottens didn’t start on this project just to stay occupied, however that takes nothing away from the level of detail involved, which is just incredible. Standing 2.4 metres high and featuring eight motors and more than 300 gears, the crane is able to perform a wide range of operations which include driving, steering and deploying the outriggers. Remote boom functions also include raising and extending the 2.4 metre fully rigged four section boom and Y-guying system, raising/lowering the counterweight, rotating the superstructure and lifting/lowering a load.

Speaking of his creation Ottens said: “After nearly 10 months of hard work I am finally able to present the Lego Technic replica of the Liebherr LTM11200 crane. It is one of the biggest roadworthy cranes in the world and I have tried to do it justice in Lego as well. This is actually a redesign of the model I made in 2013. At that time I had designed the carrier, the superstructure and the outer section of the boom. I have gone through the entire design, updated it to improve on the weak points of the original design and updated it to the newer parts that are now available. I also designed the complete boom from the ground up.”

Have a good – and hopefully creative – weekend!

Premium Cranes & Boom Lift Available For Hire & Sale

4 Special Government Schemes for Businesses Hit by Coronavirus (01-04-2020)

The Coronavirus pandemic has already affected people in India and the number is only increasing. With the national lockdown in progress, businesses are taking a hit, and finding it tedious to keep up morale and cash flow coming in.

But the Government is eager to help. Along with public and private banks in India, the Government is issuing loan schemes Schemes for businesses hit by Coronavirus outbreak in the country.

Here are some of the top schemes for businesses hit by Coronavirus:

Scheme 1: SBI Special Coronavirus Funding Scheme

India’s largest lender – The State Bank of India has drawn a funding scheme to assist small businesses who’s operations are impacted by the virus.

News update by the Times of India stated that tSBI’s new scheme – the Covid Emergency Credit Line (CECL) will be in motion up till June 30. The scheme will be equivalent to 10% of the businesses working capital limit, subject to a cap of 200 crores.

You can avail the CECL at a rate of 7.25%. There is no processing fee or pre-payment penalty for this scheme. SBI is currently the first to launch this scheme, whilst other public sector units are set to follow suit.

Important things to know about the SBI COVID-19 Loans Scheme:

- CECL will be in the form of a demand loan with a term of 12 months to help meet temporary cash flow needs.

- The loan scheme for businesses is available to all standard accounts who do not have overdue for over 30 days on Mar 16.

- Borrowers who have availed specialised loan products for small businesses are also eligible for the facility.

Scheme 2: Credit Guarantee Fund Scheme for Micro and Small Enterprises (CGTMSE)

The Credit Guarantee Fund Scheme for Micro and Small Enterprises (CGTMSE) was launched by the Government of India (GoI) to make collateral-free credit available to the MSME sector.

While this scheme is not exclusively created by the Government to

Both new and existing enterprises are eligible for this loan coverage. Under the scheme, the MSME Ministry and the Small Industries

Development Bank of India (SIDBI) established a trust named the Credit Guarantee Fund Trust for Micro and Small Enterprises (CGTMSE) to implement the Credit Guarantee Scheme.

|

Loan Amount Range |

% Guarantee Cover |

Maximum Guarantee Cover |

|

Up to Rs 5 Lakh |

85% of Loan amount |

Rs 4.25 Lakh |

|

More than Rs 5 Lakh – Rs 50 Lakh |

75% of Loan amount |

Rs 37.5 Lakh |

|

Above Rs 50 Lakh up to Rs 100 Lakh |

75% up to 50 Lakh, and 50% of the remaining amount |

Rs 62.5 Lakhs |

Scheme 3: The Atal Bimit Vyakti Kalyan Yojana Scheme

A lot of businesses are temporarily shutting shop because they are unable to pay daily wages to employees. However, this Government scheme for Businesses hit by Coronavirus provides unemployment insurance to workers who have subscribed to the Employees’ State Insurance (ESI) scheme.

The ESI is a self-financing health insurance scheme for formal sector workers in India managed by the Employees State Insurance Corporation (ESIC).

Under the scheme, workers who become unemployed due to the Coronavirus get compensation in the form of the cash up to three months of unemployment. A condition of this scheme is that it can be availed only once in a lifetime.

Scheme 4: Kerala Government Schemes for Coronavirus affected Business

There is a relief for small businesses in Kerala. The Kerala Government announced 200 billion rupees ($2.7 billion) worth of aid. The Kerala Government is also providing loans worth 2000 Crore through Kudumbashree.

The COVID relief package also ensures tax relief for passenger vehicles and an extension to bill payment deadlines for electricity and water.

Other State Government’s initiatives to help businesses affected by the virus:

Uttar Pradesh – announced cash transfers of 1,000 rupees per month to over 3.5 million day labourers and constructions workers.

Delhi – announced measures to alleviate financial stress for the poor, including up to 5,000 rupees pension to be paid to 850,000 beneficiaries by April 7, and larger rations for those entitled to food subsidies.

We will keep you posted on any new Government or Bank schemes for small businesses during this time.